Box Dividers: Creative Organizers for Product Display

-

By: Caroline Ray

-

January 15, 2025

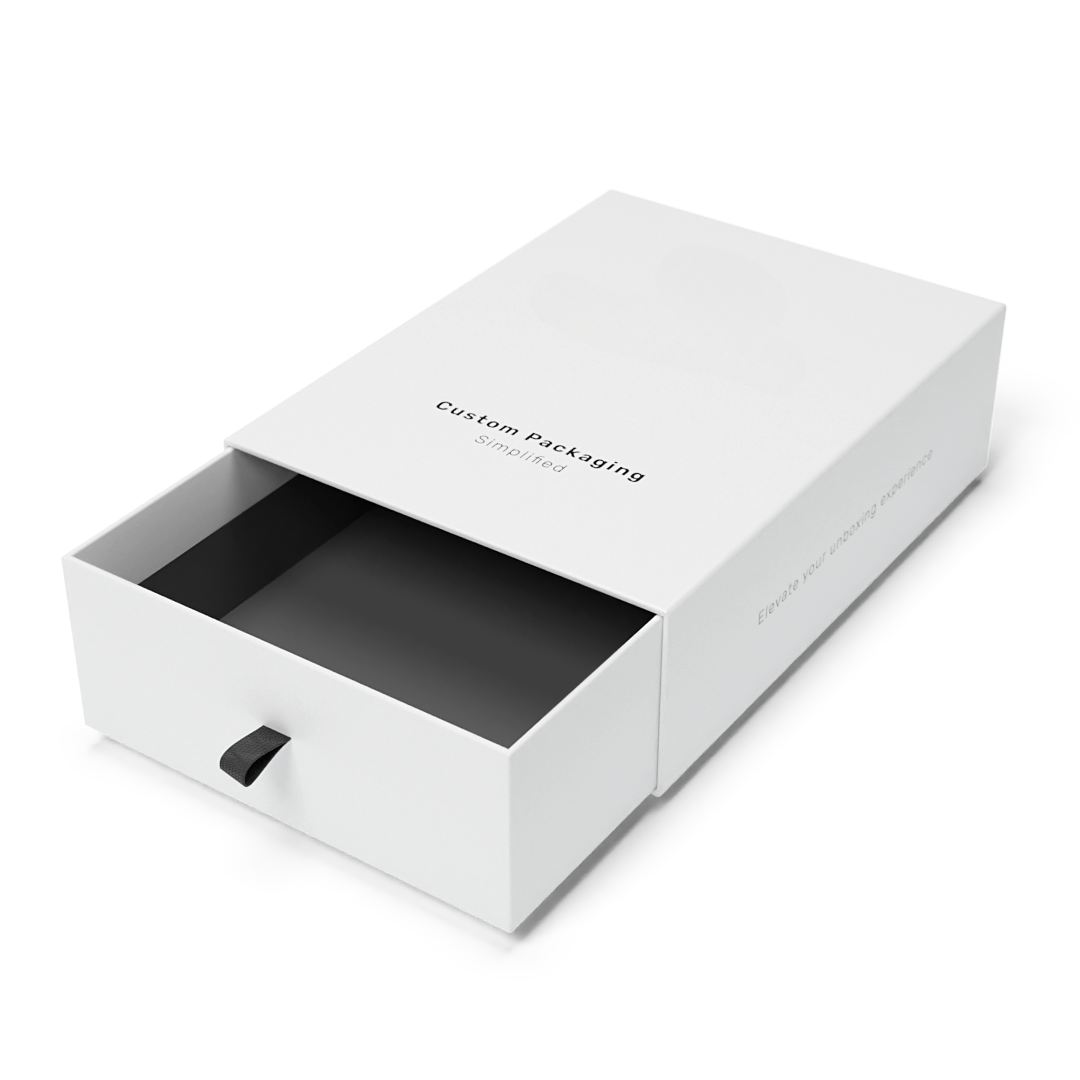

Have you ever opened a carefully crafted package only to find the contents jumbled together, facing potential damage? Enter box dividers—your essential tool for organization and protection in packaging. These ingenious and versatile organizers are not only pivotal in securing items during transit but also in creating distinct sections within a single box, addressing an array of storage needs. Explore how diverse materials like corrugated cardboard and plastic cater to different item weights and protection requirements. Discover customization options that can elevate your brand’s identity with functional elegance. Whether for eCommerce or personal use, box dividers hold the key to an efficient and memorable unboxing experience.

Box Dividers: Types and Uses

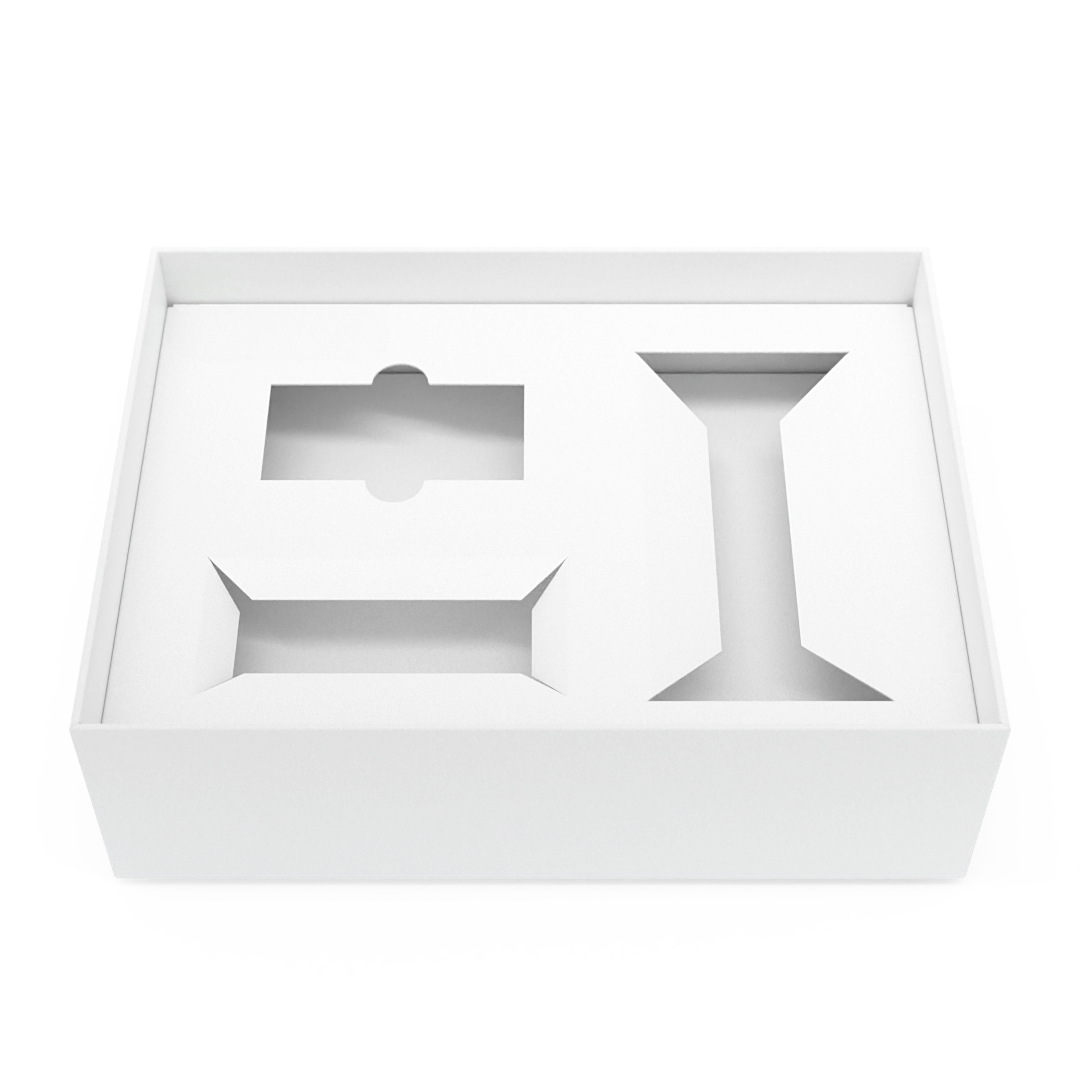

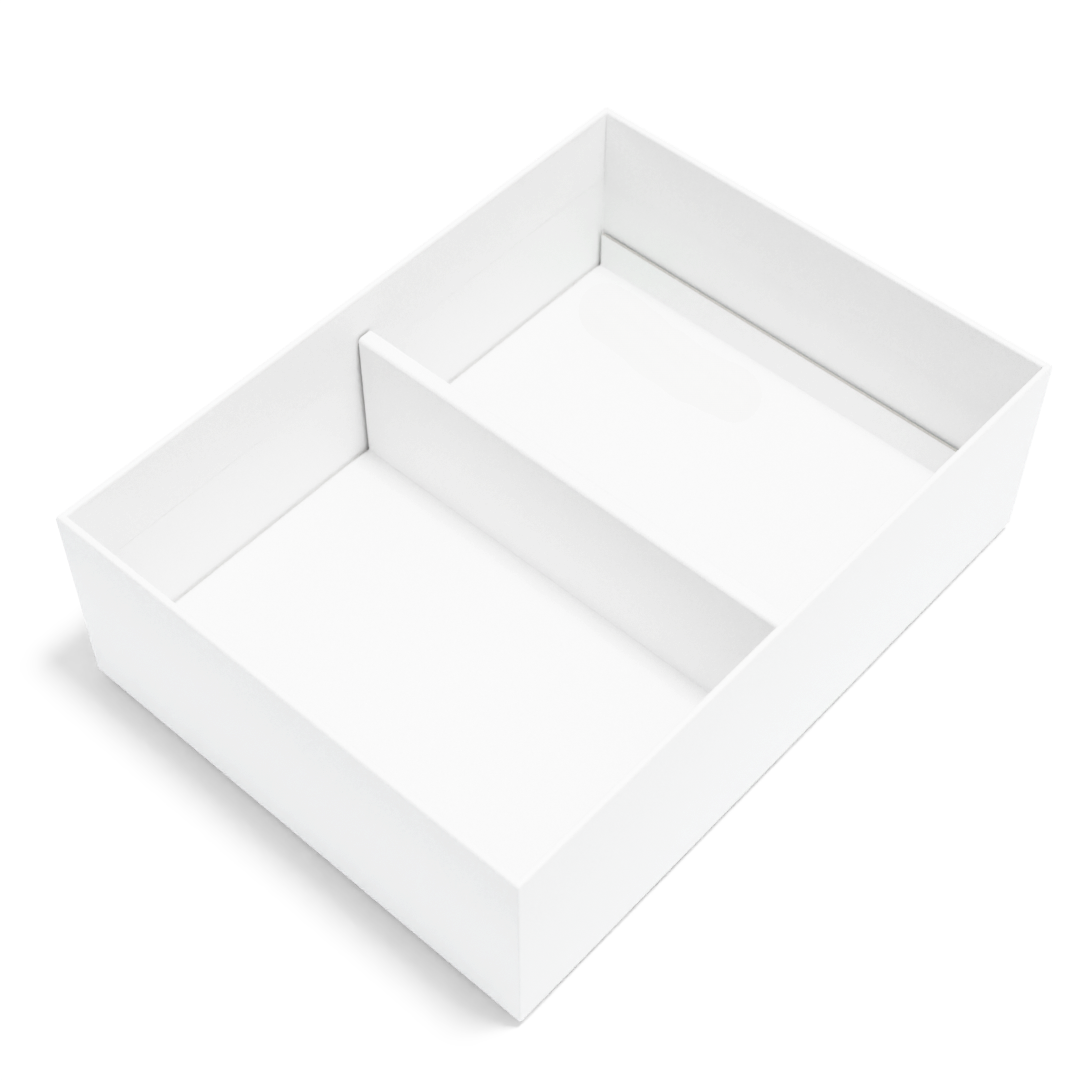

Box dividers are essential tools for creating organized compartments within packaging, ensuring that items are kept separate to prevent movement and damage. By segmenting the interior of a box, dividers protect contents from shifting during transit, which reduces the risk of breakage or abrasion. Whether used in shipping or storage, these dividers enhance organization by keeping items neatly arranged, making it easier to locate them when needed. Their ability to improve item stability makes them invaluable in logistics and warehousing, where maintaining product integrity is crucial.

The choice of materials for box dividers plays a pivotal role in their effectiveness. Cardboard box dividers are popular for their versatility and cost-effectiveness, making them suitable for a wide range of applications, especially for lighter items. For heavier or more delicate products, corrugated dividers offer additional strength and protection, thanks to their multi-layer construction. Plastic dividers, on the other hand, provide durability and moisture resistance, making them ideal for environments where exposure to liquids or humidity is a concern. Selecting the appropriate material is key to ensuring the dividers meet the specific weight and protection needs of the items being stored or transported.

- Storage organization

- Item protection during shipping

- Space maximization

- Custom branding potential

- Improved packing efficiency

Customization of box dividers allows businesses to extend their branding efforts and enhance the user experience. By altering the size, number of compartments, and incorporating printed designs, companies can create a unique unboxing experience that resonates with customers. This personalization not only reinforces brand identity but also adds perceived value to the product itself. Through custom printing, logos, and other brand elements can be displayed directly on the dividers, offering a subtle yet effective way to make a lasting impression.

Choosing the Right Box Dividers for Your Needs

Selecting the appropriate box dividers requires careful consideration of several factors, including the box size, the weight of the items, and their specific storage or shipping requirements. For example, a storage box with dividers may require a different approach than a tool box or packaging for shipping. When dealing with heavy or fragile items, corrugated dividers are often the best choice due to their enhanced strength and protective qualities. These dividers can prevent movement and provide cushioning during transit. In contrast, lighter items or those stored in a controlled environment might only need basic cardboard dividers. For tool boxes, adjustable dividers can offer exceptional flexibility, allowing users to customize compartment sizes to fit a variety of tools and accessories, thus maximizing storage efficiency.

The adaptability of adjustable and custom dividers is a significant advantage, particularly when dealing with diverse or frequently changing inventory. Adjustable dividers can be repositioned to accommodate various item sizes, making them ideal for dynamic storage needs. Custom dividers offer additional benefits, such as tailored compartment sizes and the ability to include branding elements, further enhancing organization while promoting brand identity. This customization ensures that the dividers not only fit the items perfectly but also align with specific business or personal requirements, providing a comprehensive solution for efficient organization.

DIY Box Dividers: Materials and Steps

Creating DIY box dividers offers significant advantages, primarily in terms of cost savings and customization. By making your own dividers, you can tailor them to perfectly fit your specific needs, whether for storage, shipping, or organization. This approach allows for flexibility in design, accommodating unique sizes or shapes of items that pre-made dividers might not support. Additionally, DIY dividers provide an opportunity to incorporate personal touches or branding, enhancing the overall presentation and functionality of the storage solution. The ability to customize layouts also ensures that space is maximized efficiently, ultimately contributing to better organization.

For those interested in making their own dividers, the process requires only a few basic tools and materials. Cardboard is a popular choice for DIY projects due to its accessibility and ease of use. A ruler and utility knife are essential for measuring and cutting the cardboard to the desired dimensions. For those opting for more durable plastic dividers, materials like polypropylene are recommended, though tools such as a table or circular saw might be necessary for cutting. Both cardboard and plastic offer distinct benefits, with cardboard being more cost-effective and plastic providing greater durability and moisture resistance.

- Measure the interior dimensions of your box.

- Mark and cut cardboard or plastic sheets to size.

- Score the sheets where they will be folded or slotted.

- Assemble by inserting each piece into the corresponding slots.

- Test the fit within the box and adjust if necessary.

- Secure with tape or adhesive for added stability.

Ensuring a snug fit and durability of your DIY box dividers requires attention to detail. Precise measurements are critical; any errors can lead to ill-fitting dividers that fail to hold items securely. When assembling, it is important to test the fit and make any necessary adjustments to ensure stability. Using tape or adhesive to secure the joints can further enhance the divider’s robustness, especially for heavier items. These steps not only extend the lifespan of the dividers but also enhance their capacity to protect and organize contents effectively.

Purchasing Options for Box Dividers

Custom dividers offer a versatile solution for businesses seeking to enhance their packaging. When considering purchasing options, bulk orders often present the most cost-effective method, particularly for large-scale operations. Customization is a significant aspect of this process, enabling companies to tailor dividers to specific dimensions, materials, and designs that align with their brand identity. The minimum order quantity for custom dividers typically starts at 300 units when ordered alongside an outer box and 500 units for standalone dividers. This flexibility allows businesses to adjust based on their operational needs, whether they require simple cardboard dividers or more robust, printed partitions. Online platforms make the ordering process straightforward, offering quotes and dedicated support to assist with design and material choices while providing various finishes like matte or glossy to enhance the visual appeal.

- Box size

- Material choice (corrugated, non-corrugated)

- Printing and customization

- Order quantity

Selecting a reliable supplier is crucial to ensure that the dividers meet quality standards and align with branding goals. Aigo Print Shop is one option known for its comprehensive support and range of customization choices, making it a valuable resource for businesses seeking top-notch packaging solutions. When choosing a supplier, factors such as customer support, the variety of available options, and the ability to meet specific design requests should be prioritized. This ensures that the dividers not only fulfill their functional purpose but also contribute positively to the overall customer experience, reflecting the brand’s commitment to quality and attention to detail.

Innovative Uses for Box Dividers

Traditionally, box dividers have been employed primarily in shipping and storage to create compartments that prevent movement and damage during transit. Their role in organization is well-established, with dividers keeping items neatly arranged, thereby facilitating easy access and inventory management. These practical applications are invaluable in logistics and warehousing, where maintaining order and protecting goods are crucial. By segmenting spaces within boxes, dividers efficiently separate items, enhancing both protection and accessibility.

Beyond these conventional applications, box dividers have found innovative uses across various environments. In home organization, they serve as creative storage solutions, adapting to diverse needs such as organizing closets or managing craft supplies. In professional settings, dividers can be part of display setups, providing structure for retail product presentations or office supply management. Their adaptability extends to seasonal storage, allowing for themed arrangements that can be customized to suit specific occasions or holidays, enhancing both functionality and aesthetic appeal.

- Closet organization

- Craft storage

- Seasonal decorations

- Retail product displays

- Office supply management

The potential for seasonal and themed storage solutions with box dividers is particularly appealing. By customizing dividers to accommodate seasonal items, users can streamline the organization of decorations or themed accessories, making them easy to locate and use. This adaptability not only maximizes storage efficiency but also adds a layer of personalization to organizational systems, making them more intuitive and user-friendly.

Final Words

Box dividers serve as versatile tools for effectively protecting and organizing items during storage and shipping. Different materials like cardboard and plastic cater to varying needs, while customization options enhance brand visibility and packing efficiency.

Choosing the right type of dividers involves considering factors such as item weight and box size. DIY solutions offer cost-saving benefits, while purchasing custom dividers suits specific needs. Their uses extend beyond packaging, offering innovative solutions for home and business organization.

Incorporating box dividers can improve packaging strategies and elevate the overall unboxing experience.

FAQ

How to create dividers in a box?

Box dividers can be created by cutting cardboard or plastic sheets to fit inside the box, then notching or slotting them to interlock together, forming compartments.

How to make partitions in a box?

To make partitions, measure the box’s interior and cut divider materials accordingly. Use notches or slots in the dividers to fit them together securely.

How to keep cardboard boxes together?

Cardboard boxes can be kept together by using tape or glue on their seams and corners. Reinforce with additional layers for stability and durability.

What is a corrugated divider?

A corrugated divider is a partition made from corrugated cardboard, which features fluted layers for added strength. It’s suitable for protecting heavy or fragile items.

Leave a comment