Custom Foam Inserts: Secure Your Valuables Efficiently

-

By: Caroline Ray

-

January 15, 2025

What if the security of your valuables was as simple as a custom-made shield? Custom foam inserts offer just that—a tailored protection to safeguard your items efficiently. Whether you’re a business owner needing to ship fragile goods or an eCommerce brand striving to enhance the customer unboxing experience, these inserts deliver significant benefits. Custom foam inserts not only secure items but also enhance organization and improve brand visibility, transforming a generic package into a memorable experience. Explore how custom foam inserts can be a game-changer for product safety and presentation.

Understanding Custom Foam Inserts

Custom foam inserts are meticulously crafted to fit specific shapes and sizes, providing protection and organization for a wide array of items. These inserts are predominantly utilized in packaging, equipment protection, and organizational applications. By ensuring that each item is securely held in place, custom foam inserts mitigate the risk of damage, particularly during transportation. Their use extends across various industries, from safeguarding delicate electronic components to organizing tools in a workshop. Whether for commercial or personal use, the versatility of foam inserts makes them indispensable for anyone looking to protect valuable assets.

- Polyurethane: Known for its excellent cushioning properties, making it ideal for delicate items.

- Polyethylene: Offers superior resistance to moisture and chemicals, suitable for outdoor applications.

- Cross-linked Polyethylene: Provides enhanced durability and a finer cell structure, often used for high-end products.

Customization options for foam inserts are extensive, allowing users to select the type of foam material that best suits their needs and preferences. These options include not only the material but also the color and density, which can be adjusted to align with specific branding or functional requirements. The ability to customize these features ensures that the foam inserts not only provide optimal protection but also complement the aesthetic and practical demands of the items they safeguard. This level of customization highlights the importance of custom foam inserts in both enhancing the longevity of products and maintaining a professional appearance.

The Process of Creating Custom Foam Inserts

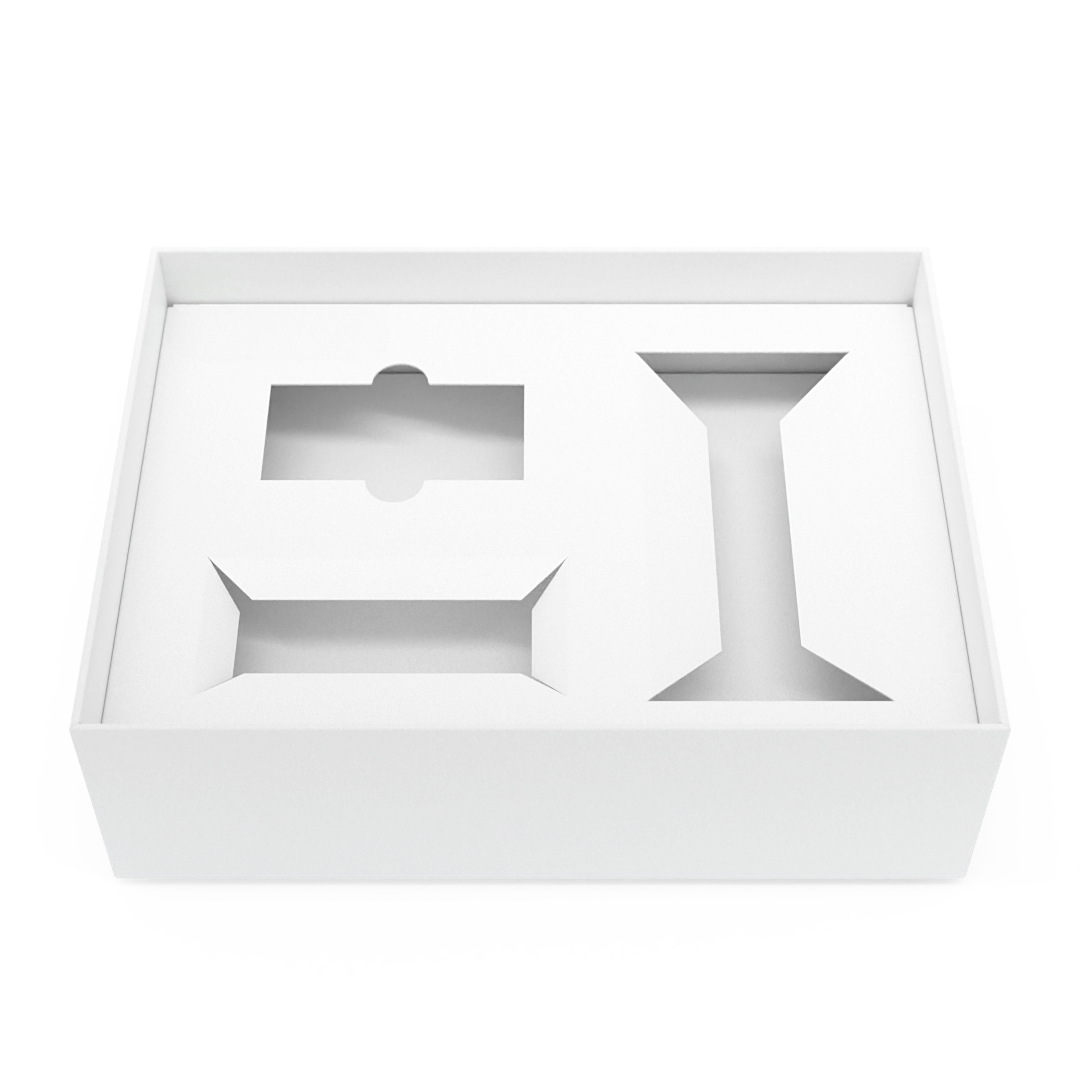

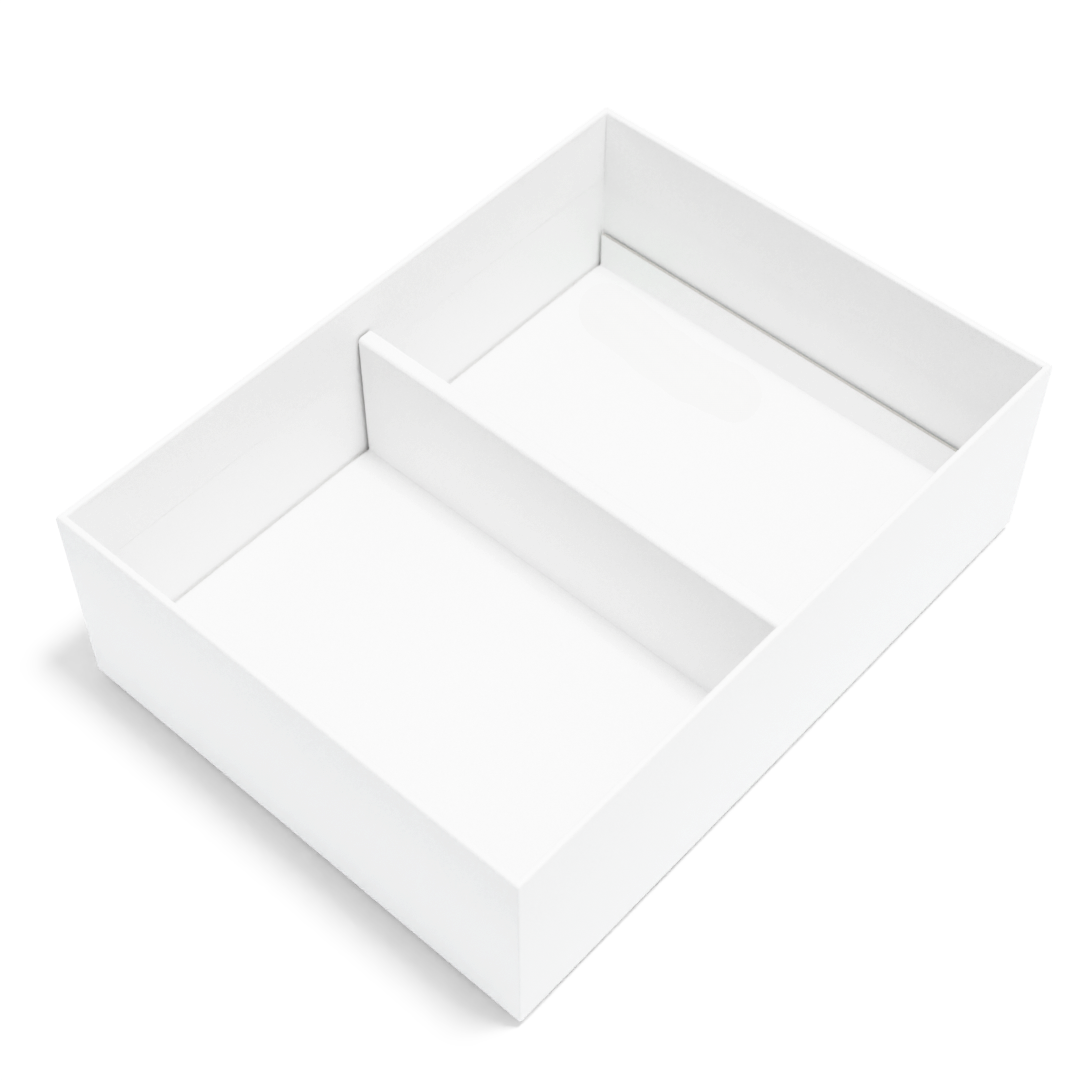

The creation of custom foam inserts begins with precise measurement and design. Accurate measurement of the items to be stored or protected is crucial to ensure a snug fit and optimal protection. This involves assessing the dimensions of each item and the available space within the intended container. Designing the layout requires strategic planning to maximize space efficiency while maintaining accessibility. Software tools can aid in visualizing different configurations, ensuring that the design meets both functional and aesthetic requirements.

The next phase involves the cutting process, where foam cutting services utilize high-quality methods such as laser cutting to achieve precision. Laser-cut foam inserts offer unparalleled accuracy, allowing intricate designs and complex shapes to be crafted with minimal waste. This technology ensures clean edges and exact dimensions, enhancing the fit and finish of the inserts. High-quality foam cutting not only improves the aesthetic appeal but also contributes to the durability and functionality of the inserts, as it minimizes the risk of errors that could compromise the protective capabilities.

Opting for professional services, such as those offered by Aigo Print Shop, provides several advantages over DIY methods. Professional foam cutting services guarantee an engineered fit, saving time and effort while ensuring a high-quality, durable solution. These services offer increased sustainability, as they employ precise cutting techniques that reduce material waste. Moreover, professionals have the expertise to handle complex designs and accommodate specific customer requirements, resulting in custom foam inserts that not only protect but also enhance the presentation of the stored items.

Comparing Foam Types for Custom Inserts

Various foam types are available for custom inserts, each offering distinct characteristics tailored to specific applications. Polyurethane foam stands out for its excellent cushioning properties, making it ideal for protecting delicate items from impact. In contrast, polyethylene foam is prized for its superior moisture and chemical resistance, which makes it suitable for outdoor or high-humidity environments. Cross-linked polyethylene, with its enhanced durability and fine cell structure, is often chosen for high-end products requiring robust protection. Each foam type can be custom cut to fit specific dimensions, ensuring a precise and secure fit for any application.

- Polyurethane: Offers excellent cushioning, ideal for delicate items.

- Polyethylene: Provides moisture and chemical resistance, suitable for outdoor use.

- Cross-linked Polyethylene: Known for durability and a fine cell structure, perfect for high-end products.

- Foam Density Options: Allows customization to provide the right balance of firmness and flexibility.

Selecting the appropriate foam type depends on the specific needs of the application. For instance, if moisture resistance is a priority, polyethylene foam would be the best choice. Conversely, for applications requiring superior cushioning, polyurethane would be more appropriate. Customers also have the option to choose the density and color of the foam to complement their branding or functional requirements. By carefully considering these factors, users can ensure that their custom foam inserts provide optimal protection and enhance the presentation of their valuable items.

Benefits of Using Custom Foam Inserts

Custom foam inserts offer significant protective benefits during shipping by providing a high level of foam cushioning. They are specifically designed to absorb shock and vibration, which is crucial for safeguarding fragile or sensitive items. Foam protection for shipping ensures that products remain intact even when subjected to rough handling or transportation conditions. By tightly securing items, these inserts prevent movement within the packaging, thereby minimizing the risk of damage. This protective advantage is particularly important for industries that ship delicate electronics, medical equipment, or any high-value items.

In addition to protection, custom foam inserts improve organization and present a professional appearance. By precisely fitting each item, they help maintain an orderly arrangement, making it easier to locate and retrieve items quickly. This organizational benefit is especially valuable in environments like workshops or manufacturing facilities where efficiency is key. Furthermore, the custom foam packaging offers a polished, professional look, enhancing the overall presentation of products. This aesthetic appeal can be crucial for businesses that want to convey a high-quality image to their clients or customers.

Testimonials and case studies frequently highlight the effectiveness of custom foam inserts in extending the life of equipment and improving storage efficiency. Users report that well-designed foam inserts increase the longevity of their items by providing consistent support and protection. Case studies often demonstrate how custom foam solutions reduce damage rates during transit, leading to cost savings and improved customer satisfaction. The ease of access provided by these inserts further reinforces their value, as users can quickly and efficiently retrieve what they need without disrupting the arrangement.

DIY vs. Professional Custom Foam Inserts

DIY foam inserts are attractive to many due to their perceived cost savings and the flexibility of creating a personalized fit for specific items. The possibility of customizing inserts at home without waiting for production turnaround can be appealing, especially for small projects or hobbyists. However, these advantages come with notable challenges. DIY case foam requires a significant investment of time and labor, particularly when creating multiple units. Achieving precise cuts and fits can be difficult without specialized equipment, leading to potentially wasted materials and suboptimal protection levels. For those without the necessary tools or experience, the complexity of DIY projects can outweigh the benefits, especially when high-quality results are essential.

In contrast, professional custom foam inserts offer a streamlined solution with several advantages. These inserts are meticulously engineered to match the precise size and specifications of components, resulting in a superior fit and finish. Professional services typically employ advanced techniques, such as CNC or laser cutting, ensuring clean edges and consistent quality across all units. Furthermore, opting for professional production enhances sustainability by reducing material waste through precise cutting methods. The expertise of professionals also means that intricate designs or complex requirements can be easily accommodated, ensuring that the inserts not only protect but also present items in the best possible manner.

- DIY Pros: Cost-effective for small projects, flexibility in design, immediate availability.

- DIY Cons: Time-intensive, requires precision tools, potential for material waste.

- Professional Pros: High-quality fit, durable materials, sustainable production methods.

- Professional Cons: Higher upfront costs, longer lead times for production.

- Suitability: DIY for small-scale, simple needs; Professional for large-scale or complex projects.

Choosing between DIY and professional foam inserts depends largely on the scale and complexity of the project. For small, simple projects where immediate results and low costs are priorities, DIY foam inserts might be suitable. However, for larger quantities, intricate designs, or when the highest quality is essential, professional services are the better choice. They provide the assurance of durability, precise fit, and the ability to meet specific requirements without the hassle and potential pitfalls of doing it yourself.

How to Measure for Custom Foam Inserts

Accurate measurements are crucial for creating custom foam inserts that securely fit and protect your valuables. The correct sizing ensures that every item is snugly accommodated, preventing movement and potential damage during transport or storage. When considering case foam selection, it is essential to account for the depth, size, and shape of both the case and the items to be stored. An improper fit could compromise the protective qualities of the foam, undermining its ability to safeguard your valuables effectively. Properly measured and fitted inserts not only enhance protection but also improve the overall aesthetic and functionality of the packaging.

- Measure the dimensions of each item, including length, width, and height.

- Determine the available space within the case, factoring in any unique contours.

- Consider the depth of foam required, including options for multiple layers.

- Use measurement tools like calipers or rulers for precise accuracy.

Advanced techniques, such as creating a .dxf file, offer precision in designing foam inserts for CNC cutting. This method involves generating a calibrated illustrator image that translates exact measurements into a digital file, which can then be used to produce inserts with unparalleled accuracy. This approach is particularly useful for complex shapes or high-volume production, ensuring that each insert is crafted to precise specifications. By utilizing these advanced techniques, users can achieve a superior fit and finish, maximizing the protective and organizational benefits of custom foam inserts.

Final Words

Harnessing custom foam inserts involves understanding their diverse applications, from packaging to organization. This blog detailed the creation process, emphasizing professional foam cutting for precision and protection. By comparing foam types, readers gained insight into matching materials with specific needs. The benefits of foam inserts in shipping and organization illustrated their value, supported by case studies and testimonials. The choice between DIY and professional options highlighted considerations for each approach, focusing on fit and sustainability. Measuring techniques ensured correct fit, reinforcing the versatility of custom foam inserts. Aigo Print Shop provides expert solutions, enhancing both protection and aesthetic appeal.

FAQ

Q: Where can I find custom foam inserts near me?

Professionally made custom foam inserts can be sourced from local packaging or foam cutting services, ensuring tailored protection and an engineered fit for various items.

Q: What types of custom foam inserts are available for cases and gun cases?

Custom foam inserts can be designed specifically for cases, including gun cases, to provide tailored protection and organization by fitting the items’ specific shapes and sizes.

Q: How can I create custom foam inserts?

Creating custom foam inserts involves accurately measuring the items, designing the layout, and cutting the foam, often using precision tools like laser cutters for an exact fit.

Q: What types of foam are used for custom inserts?

The main types of foam for custom inserts are:

- Polyurethane: Offers excellent cushioning properties.

- Polyethylene: Provides good moisture resistance.

- Cross-linked Polyethylene: Known for durability and resistance to environmental factors.

Q: Are there cheap options for custom foam inserts?

Affordable options for custom foam inserts include choosing cost-effective materials and engaging with services that offer competitive pricing without compromising quality.

Q: Can I get custom cutouts for Pelican cases?

Yes, custom foam inserts can be specifically designed for Pelican cases to ensure a perfect fit for the equipment within, enhancing protection and ease of transport.

Q: What is the benefit of using professional services for custom foam inserts?

Professional services for custom foam inserts provide high-quality, durable solutions with precision engineering, saving time and effort while ensuring optimal protection and organization.

Leave a comment